Testing

Xenon Arc Testing

ASTM G155 – Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

Aion UV’s proprietary digital paint technology was independently evaluated for ultraviolet and weathering durability.

Testing was conducted using a modified ASTM G155 Xenon Arc method, which simulates long-term exposure to sunlight, heat, and moisture on coated materials.

Test Method

The Xenon Arc test cycles ultraviolet light and water spray to replicate harsh outdoor environments.

Apparatus: Xenon Arc light chamber per ASTM G155

Cycle: 2-hour intervals

1 hour 42 minutes light

18 minutes light + water spray

Irradiance: 0.55 W/m²/nm @ 340 nm

Evaluation intervals: Every 200 hours

Measured properties: ΔE (color change CIELAB D65/10), 60° gloss retention, and adhesion/peeling

Failure criteria:

1. Color change > ΔE 2.0

2. Gloss < 20 G.U.

3. Loss of adhesion (peeling of printed layer)

Testing continued until any of these failure modes were observed for each specimen.

Conclusion

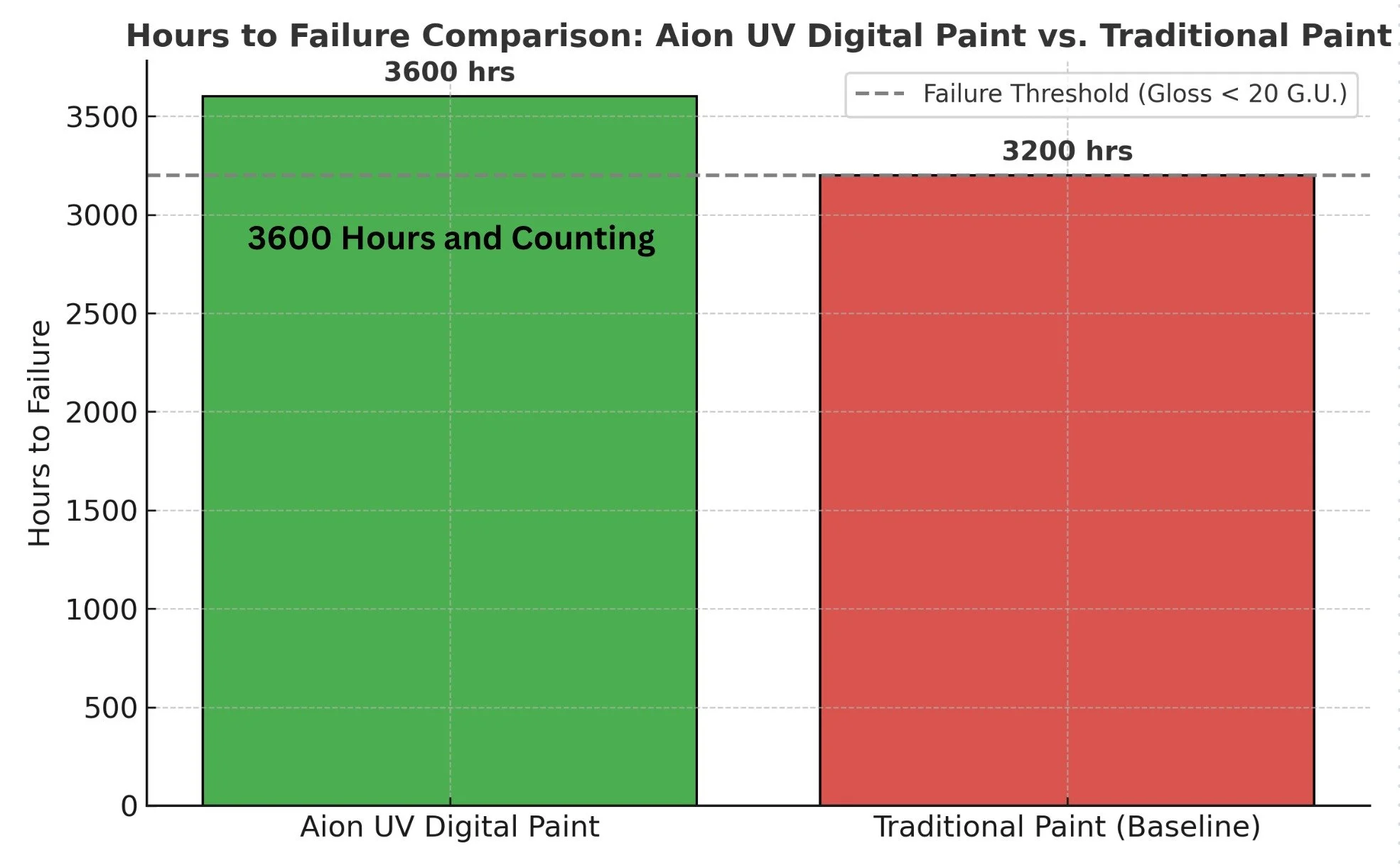

Under accelerated UV and moisture exposure, Aion UV Digital Paint maintained color stability, gloss, and adhesion for over 3,600 hours (and counting), surpassing traditional paint systems by roughly 400 hours and outperforming all other tested specimens.

These results demonstrate the exceptional longevity and fade resistance of Aion UV’s digitally applied coatings, providing OEM-level durability for RV and industrial applications with a precision finish and sustainable production process.

QUV (Quick Ultra Violet) Test

This tests for color change, Gloss Retention, Chalking, Cracking, Blistering, and Adhesion.

Time (Hours)

Length of QUV Testing

Aion UV digital paint chemically bonds with substrates, ensuring exceptional durability. Our most recent QUV test showed no visible changes after exposure 6 times longer than “standard” paint durability and 2 times longer than “exceptional” paint durability.

Note: Accelerated weathering tests, like QUV testing, simulate years of outdoor exposure in a short period. However, the hours spent in the test chamber do not directly translate to actual hours of product life in real-world conditions. Instead, these tests provide comparative data to predict long-term durability.

OEM Testing

Testing has been conducted by several OEMs including 2 of top 3 manufacturers

Adhesion test - Two surface scratch tests determine the adhesion level to the American Society for Testing and Materials standard.

Gloss test - Gloss meter used to determine gloss level before and after the weather chamber.

Hot/Cold test - Heat soak for seven hours followed by freezing overnight. This process is repeated in a three-day cycle.

Water test - Three-day water soak test for any flaking or damage to the surface. The water-soaked sample is transferred into a freezer overnight to review for cracking.

Chemical/Stain test - Tests for any permanent damage to the surface coating.

Pencil Hardness test - Two surface scratch tests determine scratch resistance and hardness level to the American Society for Testing and Materials standard.

Gravelometer - Tests for damage resistance to rock impacts.

Infrared Heat Cycling Delamination Test: This test evaluates the structural integrity and adhesion performance of digitally painted RV exterior wall systems when subject to rapid temperature fluctuations.